Steel with different properties is used to make knives, which means that each knife requires specific sharpening using suitable stones. In this article, we'll introduce you to the big breakdown of whetstones and teach you which knife whetstone you need to get maximum performance.

There is a large number of whetstones, so it can be difficult to navigate. However, with a little effort, you can handle it.

What all sharpening stones have in common:

All types of sharpening stones for knives are characterized by different grain sizes, which are indicated by a number referred to as. The grain value is one of the decisive factors when buying. The lowest value means the coarsest grain, while the highest value represents the finest grain

Low number stones (such as 200 grit) are suitable for smoothing out unevenness and repairing a damaged edge.

Stones with a higher grain size (400 and more) are suitable for the sharpening of knives that are not damaged, but have not been sharpened for a long time.

Grinding stones with values (600 to 3,000) are intended for basic care. You will use them for continuous sharpening of knives, which are not dull, but you need to always have them ready and sharp.

The highest grit values (4,000 to 10,000 grit) are intended for polishing the knife, tightening the edge and smoothing it almost to perfection. They are used for already sharp knives.

Tip

If you decide to start sharpening knives yourself, it is necessary to secure several whetstones for youself, with different grits.

Basic division of grinding stones:

We divide sharpening stones for knives into several categories. However, the most basic division is according to their origin:

- natural,

- synthetic.

We can supplement this division with other categories, such as:

- japanese,

- combined,

- water,

- oil,

- diamond.

Natural sharpening stones

Quartz, slate and some types of sandstone are used to sharpen knives. For example, the Rozsutec grinding stone is made of this material, which is characterized by high hardness and durability. This also applies to other natural stones, such as American Arkansas or Belgian Ardennes Coticule.

The disadvantage of these natural stones can be the inhomogeneity of the grain, which can lead to an uneven grinding result. In addition, these stones are more expensive, since the acquisition of material and production are more expensive.

The degree of gradual wear is also an important factor when choosing a grinding stone. With natural stones, wear is less, but due to their structure and hardness, grinding takes longer.

In the case of natural stones, it is not possible to perfectly determine the grain size, but it can be fairly accurately estimated from experience.

Synthetic grinding stones

It is mainly artificial corundum (aluminum oxide), from which grinding stones, such as Taidea or Tyrolit grinding stone, and silicon carbide are also made. These stones are characterized by hardness and reliability, as corundum is the second hardest mineral after diamond. They enable the sharpening of carbon and stainless steel and can also handle titanium alloys.

Compared to stone materials of natural origin, these stones have a precise grain and a consistent surface.

However, even these stones wear out and lose their flatness. The material from them decreases unevenly, so a leveling stone is used for their maintenance.

Currently, these are the most widespread and used stones on the market.

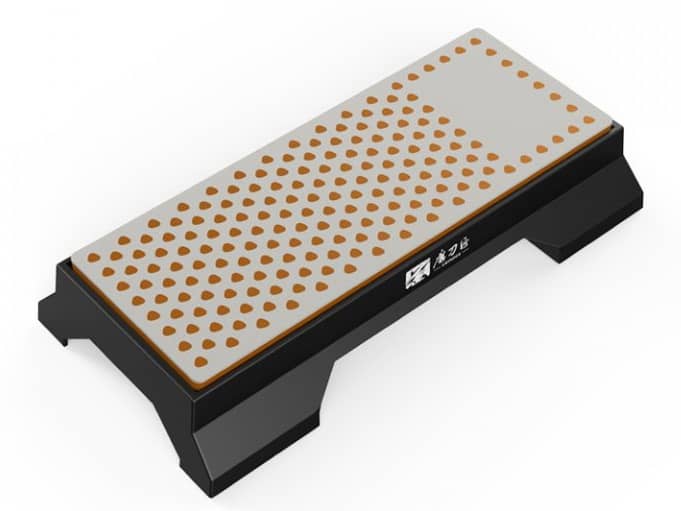

Diamond grinding stones

Diamond is the hardest material in the world and is recommended for sharpening knives made from hard types of steel. In the case of diamond grinding stones, these are single crystals of diamond embedded in a nickel matrix, which are applied to a steel plate using electrolysis. Although the layer of deposited particles wears away over time, the plane of the surface remains unchanged.

When grinding, it is advisable to combine the use of stones. For example, you can use the FällknivenDC521, which combines a diamond whetstone for sharpening the blade and a finer ceramic stone for finishing the grind.

Diamond stones are resistant to damage and enable faster sharpening of knives compared to ceramic stones of the same grain size. They are used for dry grinding without applying oil or water.

Use water only for cleaning. Simply rinse them after use.

Japanese whetstones

Grinding stones from this country were and still are among the highest quality and most effective. They are known for their high hardness, thanks to which you can sharpen knives quickly and achieve exceptional sharpness. You can easily remove all minor defects and damages with them. The ideal stone for this job is Shapton Glass Stone 3000.

Today, even Japanese manufacturers use synthetic materials, but the quality and precision have remained. A wide range of stones makes it possible to sharpen all types of knives and steels. This category overlaps very closely with synthetic whetstones, also known as Japanese waterstones. They are used exclusively for sanding with water, i.e. wet.

Interesting

The original Japanese whetstones were made from material mined directly in Japan. Currently, almost all quarries are closed.

Combined grinding stones

These stones are usually composed of two or more synthetic stones with different grain sizes that are bonded together.

With one of the stones, you can sharpen damaged blades more intensively, with the second one, you can fine-tune the blade, and with the third stone, you can further polish and smooth them. The stone that meets all these requirements is Taidea 240/1000/3000.

The disadvantage of these stones is their higher one-time price. Ultimately, however, they will pay off more in terms of efficiency, convenience and finances.

Water and oil grinding stones

The difference between these types of grinding stones lies in the binder that holds together the material intended for grinding. In the category of water stones you can find, for example, Taidea 2000 and in the category of oil stones Arkansas. With both types of whetstones, you can sharpen all types of knives and blades, while the result depends on their grit.

Grinding creates friction and heat, so some stones use water for lubrication and cooling, others oil, and some both. Cooling reduces the risk of damage to the knife and sharpening stone and extends their life.

Expert advice

Before grinding, water grinding stones must be soaked in water for approximately 10 minutes. If the stone dries out during grinding, it must be wetted again. This can happen if you sharpen multiple knives and do it for a long time.

However, this process is not necessary with diamond grinding stones. Water is used only to clean the stone.

With oil grinding stones, it is necessary to use a little oil. It is enough to use only a few drops for sanding.

How to choose the right grinding stone? Each type of grinding stone has its specific advantages and disadvantages. Now you know the characteristics and basic information about sharpening stones for knives that are available on our market. If you decide to sharpen your knives yourself, you can easily choose the right whetstone for you.

Which stone you choose depends only on your discretion and especially on your needs. Whatever you like, take your pick.